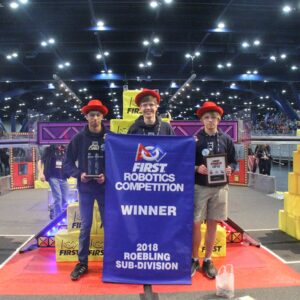

The Harker robotics team competed at San Jose State University in April, the second competition of the robotics season and their last chance to qualify for the national competition. This drive team competed at UC Davis in early March and finished the preliminary rounds in the top 10 teams, but a malfunction in one of their alliance member’s robots meant that Harker and its partner robots were literally blocked from scoring.

At the San Jose event, the team went in with high hopes and a “113.5 pound, lean, mean, extremely tough machine,” said Peter Gao, grade 12, executive president of the team, which is run as an enterprise. Although the team did not advance to the national level, the experience of building and running the robot was the real value in the effort.

The robot was constructed entirely by students, with guidance from Eric Nelson, physics and astronomy teacher. This year, they built a simple and reliable robot to make it easily repairable and maintainable between matches. This simpler design, pioneered by team members Pranav Bheda, grade 10 and Jason Yu, grade 11, brought durability to the robot, as well as decreased construction time. Instead of having to finish building the robot very near to the competition date, the robotics team finished the robot with two weeks to spare, giving them a chance to develop a well-practiced drive team, well-prepared for competition.

After the San Jose event, Gao analyzed what went wrong. “On one hand, our driver was kind of rusty because the last competition was a few weeks before, and we didn’t give him sufficient practice time,” he said. “Also, there were strange programming/electronics errors that simply shut down our robot at the beginning of the round, and we’re still not sure what’s causing them.”

Still, the team had a fair to middling shot at glory. “I think we did a lot better than previous years, though not as well as I would have liked,” said Gao. “We managed to build a functioning and capable robot a week early, and got enough practice and testing time to iron out a lot of kinks. The gains from this year are not technical, but organizational and strategic: a simpler robot whose construction is heavily planned with periodic deadlines will be completed earlier and tested more thoroughly, leading to an overall more effective robot than a more complex one that is finished right on time.”

There is always next year and Gao has a few words of advice for next year’s team: remember that simplicity and reliability are most important with a robot. Without them, the robot is ineffective. Also, a human is many times more reliable than a machine.